info@atdocksystems.com

+380-94-994-18-03

+372-56-500-610

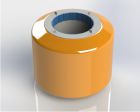

Cylindrical fender

Good old cylindrical fenders available on market for many years. Simple and versatile as well as easy to install. Their progressive reaction makes them perfect for berths serving large and small vessels special for the protection of gravity quay wall. Can be mounted on chains and steel bars.

YGCH cell fender

Current structure of this fender is the result of continious refinement, making it simple , high performance and strong. Keep same installation dimension, so they are interchangeable with many older cell fender types. The cell fenders come in wide range of standard sizes and can meet multiberthing conditions.

DO fender

DO type rubber fenders are improved products, based on D type fenders. Double wing installation can be used under the most severe conditions. Common aplications - jetties and wharves for small craft, workboat harbours, general cargo, inland waterway.

Me fender

ME fenders have very high performance. They are versatile and can be combined in many combinations of lengths and directions. Can meet several berthing conditions. Most common applications for ME fenders: container terminals, tanker berth, Ro-Ro and cruise ships berths, bulk and general cargo berths.

ST fender

ST rubber fender provide large contact area with one closed bevel end and can be used in very tough conditions. Most common applications: Jetties and wharves for small craft, workboat harbours, general cargo, inland waterway.

Composite fender

Composite fenders are the bond of rubber and UHMW-PE plate. Special vulcanising method makes them stronger and with low friction. Supplied in many standard sizes, several types of mounting method and wide color range of UHMW-PE available. Applications: jetties and wharves for small craft, mooring pontoons, inland waterways, pile guides on floating structures where low friction needed.

Cone fender

Cone fenders are the 3rd generation of cell fenders, with optimal performance and efficiency. The conical body shape is very stable even at large compression angles. They come in wide range of standard sizes, can meet multi-berthing conditions. Can support large UHMW-PE panels, can meet multi-design conditions, easy and quick installation.

DGH arch fender

DGH arch fenders are new generation of V type fenders. DGH fenders are simple and rugged so they can be used in most severe conditions. DGH-B type arch fender can be fitted with either UHMW-PE face pads or connected to steel panels. Also available arch fender with ladder and 90 degrees corner protection cover.

Floating fender

The floating fenders have rubber or polyurethane skin. The best choice for large tidal ranges and ship-to-ship transfers. Larger fenders are commonly fitted with a chain-tyre-net for additional strength.

Extruded fender

Extruded fenders are simple rubber fender profiles, usually attached with bolts to the support structure. Any length could be available for these extruded fenders. They can be cut and drilled to suit design conditions. Variable mounting methods, black and grey colors.

Pneumatic fender

Pneumatic fenders are ideal for ship-to-wharf and ship-to-ship transfers. Larger fenders are commonly fitted with a chain-tyre-net for additional protection. Different sizes available.

Step fender

Step fenders are single rubber module. Can be combined as rubber steps. They can absorp boat impact and have long service time. Thanks to unique structure design and versatile length step fenders can be applied for different design needs.

Wheel fender

Wheel fenders are widely used on exposed corners to help ships manoeuvre into berths and narrow channels such as locks and dry-dock entrances. Low rolling resistance and maintenance cost. Can be used in one or in multiple stacks.

Tug fender

Special fender solution for tug boats. This fenders work longer and under extreme conditions. Available in several types, each type serves for a particular application. Cylindrical fenders, pushing fenders (M, W, Block), side belting (DD, DC, SC), transition blocks.

Donut fender

Donut fenders are an effective solution for simple berthing dolphins, guides and turning structures. The buoyant donut floats up and down a single tubular pile and freely rotates to help align or redirect ships. Internal casing covered with long lasting, low friction material which needs minimal maintenance. Donut fenders are custom designed for every application. They can have supplementary buoyancy to present araised contact face. Bright colors are often used to improve visibility and safety.

UHMW-PE pad

Ultra high molecular weight polyethylen have low friction and can last long in most extreme environmental conditions. That`s why this material is used in marine structures very widely nowadays. We can supply custom made pads of UHMW-PE in different sizes and colors to fit design conditions.